Tree risk assessment of structural failure is of prior importance in urban trees. The potential decay inside urban trees could greatly affect the structural health and threaten infrastructures and public (Terho & Hallaksela, 2008). Without proper tools to identify the extent of decay, the assessment could not be done in a convincing way. To avoid potential danger posed by hazardous trees, tree felling is often the result and such acts are usually criticised by the public (Curle, 1991).

In Hong Kong, wood or hard plastic-made mallet is commonly adopted by arborist to identify potential cavities inside trunk and thick branches. By hammering the wood by the mallet and listening to the sound produced, an arborist can tell whether there is a cavity within and estimate the size of it.Mallet is a handy, easy tool which does not require much training. This low-cost tool provides instant result and is therefore welcomed by most arborist.

However there are many limitations within. The assessment made greatly depends on arborist’s personal experience and is therefore a subjective one. The sizeof cavity and extent of decay within the target wood can only be estimated instead of measured. A number of tree defect detection systems with different methodology can now be found on market, including TreeRadar, X-ray and Increment Borer. We will critically appraise two defect detection systems which were widely adopted in Hong Kong.

Resistograph

Resistograph is a portable device for tree decay detection. It is a like a probe with a small diameter drill of 1.5mm to 3mm (Leong, et.al., 2012) which can penetrate into the wood with constant forward speed. Decayed wood is often softer than structurally sound dense wood in term of mechanical properties. By measuring the torque required to drill through the suspected zone wood, the resistograph can accurately record the decay and sound wood lied along the route which the drill is taken. The record is then printed on a dendrogram which provide a profile on the cross section of the target zone. The operator can usually get a rough idea on the profile by feeling the changes in resistance during the drill and observe the ejected saw dust for decayed wood chips (Leong, et. al., 2012)

Limitation

Among most advance tree defect detection system on market, Resistograph is comparatively less expensive device and has a rather simple set-up procedure (Johnstone et al, 2007). Resistograph is also considered as an accurate device for tree defect detection (Costello & Quarles, 1999). However resistograph has a number of limitations.

Sound wood damage is inevitable when resistograph is deployed. The drilling path connecting bark and inner wood would lead to fungal invasion (Leong, et. al., 2012). The sapwood around the drill holes promotes the development of fungi and lead to potent decay. Also resistograph drilling can only provide a one dimension profile of the target zone, i.e. the drilling path itself. To establish a better understanding on the extent of the decay, more drilling have to be done around the target zone. However multiply drilling holes may lead to potential decline of tree’s health as there further promote fungal growth (Kersten & Schwarze, 2005).

Although the drilling paths along the target wood are supposed to be a straight line, the real situation may not be the same as the drill bit is flexible. In fact the drill bit follows the least-resistance path inside the wood, which is usually through the cavity or decay woods. Thus the drilling path can be bending around the harder woods. Such ambiguity would lead to exaggeration of decay inside the target zone and is misleading to the final result.

Improvements

Schwarze (Schwarze, 2008) suggested usage of bigger drill bits (eg. 5mm diameter) would prohibit fungi growth along the drilling path. Larger drilling holes would allow higher air circulation flow along the drilling path and avoid accumulation of water, which is a necessity for fungal development. However larger drill bits would cause higher damages to the tree. With bigger drilling bit, vibrations caused during the drilling process may lead to a greater number of internal cracks along the drilling path. Therefore number of holes to be drilled shall be carefully justified before the whole assessment take place.

Drills are made elastic so that they won’t break inside the wood. However with such elasticity,the drills would easily bend inside the wood. The result would be misleading. I would suggest developing a stronger drill bit which not only can avoid breaking inside the wood, but also able to be penetrated into the wood without bending.Meanwhile in case any bending occurs, it shall be able to be detected and properly recorded.

Acoustic Tomograph

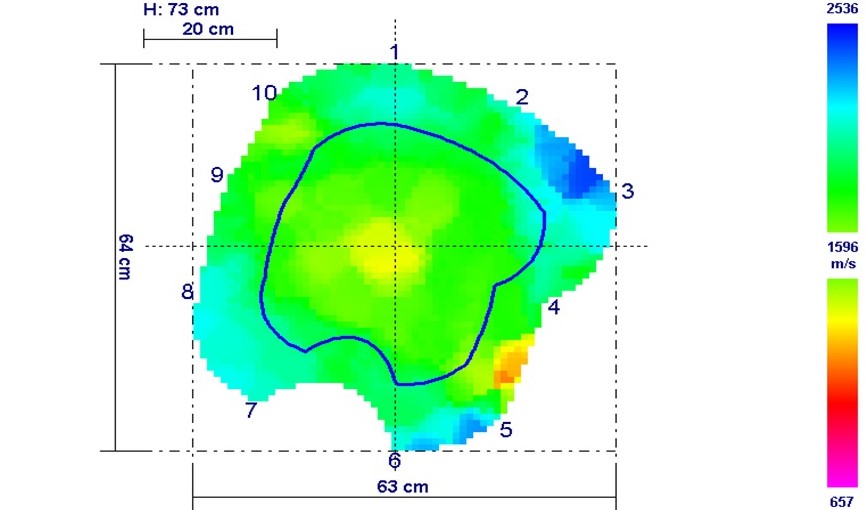

Compare to resistograph, acoustic tomograph is a less invasive device for detecting tree decay. Depending on the size of the target wood, around 10 nails with sensors attached are tapped to the cambium around the target wood. By tapping the nail, a sound wave is generated and relevant signals are picked up by other sensors. The theory behind is: sound wave velocity varies in different mediums. Since sound waves travel through sound wood and decay wood indifferent velocity, extent of decay can be known by analyses different sound wave velocity (Wassenaer & Richardson, 2009). By tapping the nails around the target wood, a two-dimensional cross section image of the tree, commonly known as tomogram, can be generated. By repeating the same procedure at different height along the tree stem, a three-dimensional comprehensive model with decay inside the wood could be constructed.

Limitation

Apart from being a less invasive device, acoustic tomograph is well recognised as an effective tool for internal decay detection (Lin et al, 2013). However compare toresistograph, acoustic tomograph is an expensive device. Acoustic tomograph involves a number of components of different sizes and weights, which made it a less ideal portable device. Also it takes longer setup time and required a well-trained operator to operate it.

Acoustic tomograph provides a full colour tomogram, a user-friendly way to present the size of the decay. However acoustic tomograph may wrongly estimate the size of internal decay. Under certain circumstances, acoustic tomograph fails to distinguish internal cracks and heartwood decay (Wang et al., 2007). It is limited to detect defects ranging from 5cm to 10cm (Leong et al, 2012). A number of cases showing decay content may not be detected, provided that the wood density is not greatly reduced by certain invasive fungus (Deflorio et al, 2007).

The accuracy of acoustic tomograph is also limited by the shape of the target wood’s cross section. Accuracy improves if the geometric shape of the trunk tends to a perfect circle, and vice versa. (Leong et al, 2012).

Improvements

Acoustic tomograph is widely adopted by arborist when visual inspection is done, especially on valuable trees. However it is of enormous important that the operator have to understand the limitations of acoustic tomograph. To have a better estimation on the extent of decay, I would recommend to put more sensors around the target wood. It also facilitates accurate reading then irregular wood shape is encountered. Such act may lead to further cambium damages as more nails are tapped on the bark. However the holes of such size would not affect the stability of the tree (Gilbert & Smiley, 2004).

Acoustic tomograph failed to detect decay if wood density do not have a significant drop, more researches should be done on relevant fungus infection so as to further our knowledge on the limitation of acoustic tomograph.

Acoustic tomograph may fail to distinguish large area of internal crack and decay. Other tree defect detection systems including TreeRadar & resistograph are able to provide supplement information for a more accurate assessment. It is in hope that a more advance acoustic tomograph will be developed in the coming future.

References

Costello, L. & Quarles, S., 1999. Detection ofwood decay in blue gum and elm: An evaluation of the resistograph and theportable drill. Journal ofArboriculture, 25(6), 317. Accessed on 05/12/2018 via: http://unri.org/ECO%20697U%20S14/costello__quarles,_1999.pdf

Curle, M., 1991. Whose responsibility? Arboric. J., (1991) Vol.15, 235-241

Deflorio, G., Fink, S. & Schwarze, F.W.M.R., 2007. Detection of incipient decay in tree stems with sonic tomography after wounding and fungal inoculation. Wood Sci Technol42:117–132

Gilbert, E.A. & Smiley, T., 2004. Picus sonic tomography for the quantification of decay in White Oak (Quercus alba) and Hickory (Carya spp.). Journal of Arboriculture 30:277–281.

Johnstone, D. M., Ades, P. K., Moore, G. M. & Smith I. W., 2007. Predicting Wood Decay in Eucalypts Using an Expert System and the IML-Resistograph Drill. Arboriculture & Urban Forestry. 33(2):76–82

Kersten, W. & Schwarze, F., 2005. Developmentof decay in the sapwood of trees wounded by the use of decay detection devices, Arboricultural Journal, 28(3), 165-181.Accessed on 05/12/2018 via: http://www.tandfonline.com/doi/abs/10.1080/03071375.2005.9747417

Leong, E.C., et al, 2012. A Purposeful Classification of tree decay detection tools. The International Journal of Urban Forestry, Vol.34, No. 2, 91-115.

Lin, C.J., Chung, C.H., Wu, M.L. & Cho, C.L., 2013. Detection of Phellinus noxius decay in Sterculia foetida tree. Journal of Tropical Forest Science 25(4): 487–496

Schwarze, F.W.M.R., 2008. Diagnosis and Prognosis of the Development of Wood Decay in Urban Trees. ENSPEC Pty Ltd., Australia.

Terho, M., Hallaksela, A., 2008. Decaycharacteristics of hazardous Tilia, Betula, and Acer trees felled by municipalurban tree managers in the Helsinki City Area, Forestry, 81(2), pp. 151-159. Accessed on 05/12/2018 via: http://forestry.oxfordjournals.org/content/81/2/151.abstract

Wang, X., Allison, R., Wang, L. & Ross, R., 2007. Acoustic Tomography for Decay Detection inRed Oak Trees, 1st ed. Madison, United States Department of Agriculture.Accessed on 03/12/2018 via: https://www.fpl.fs.fed.us/documnts/fplrp/fpl_rp642.pdf

Wassenaer, P.V. & Richardson, M., (2009). A review of tree risk assessment using minimally invasive technologies and two case studies.Arboricultural Journal, 32:4, 275-292, DOI: 10.1080/03071375.2009.9747583